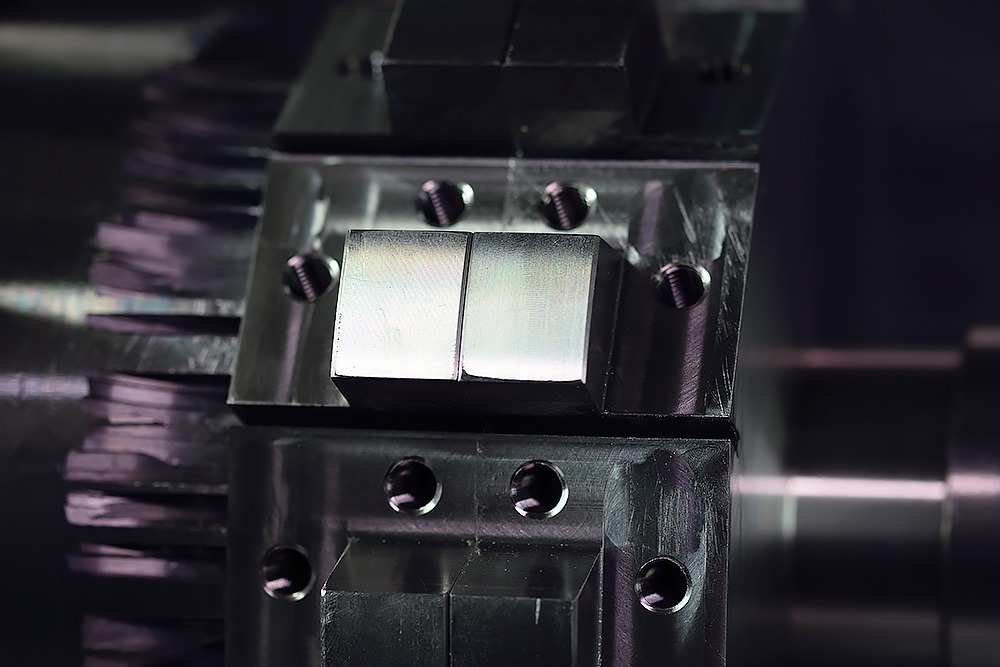

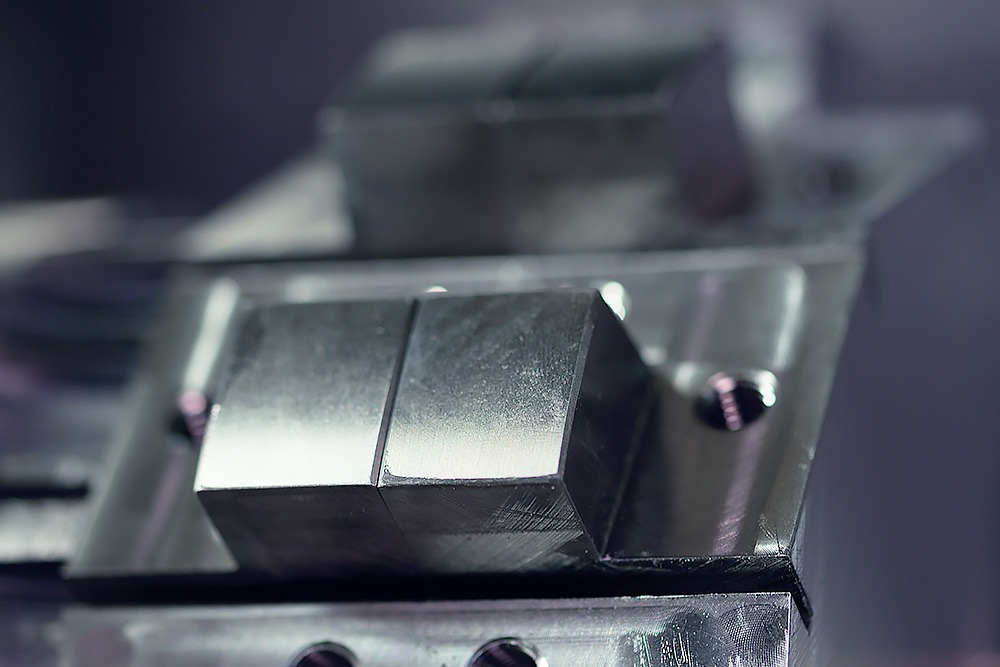

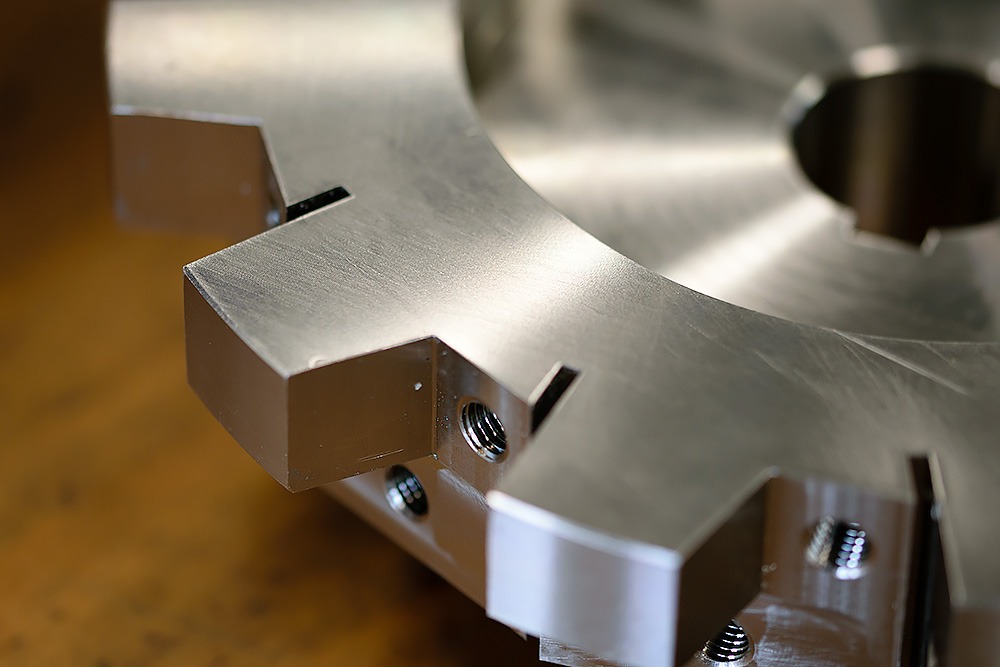

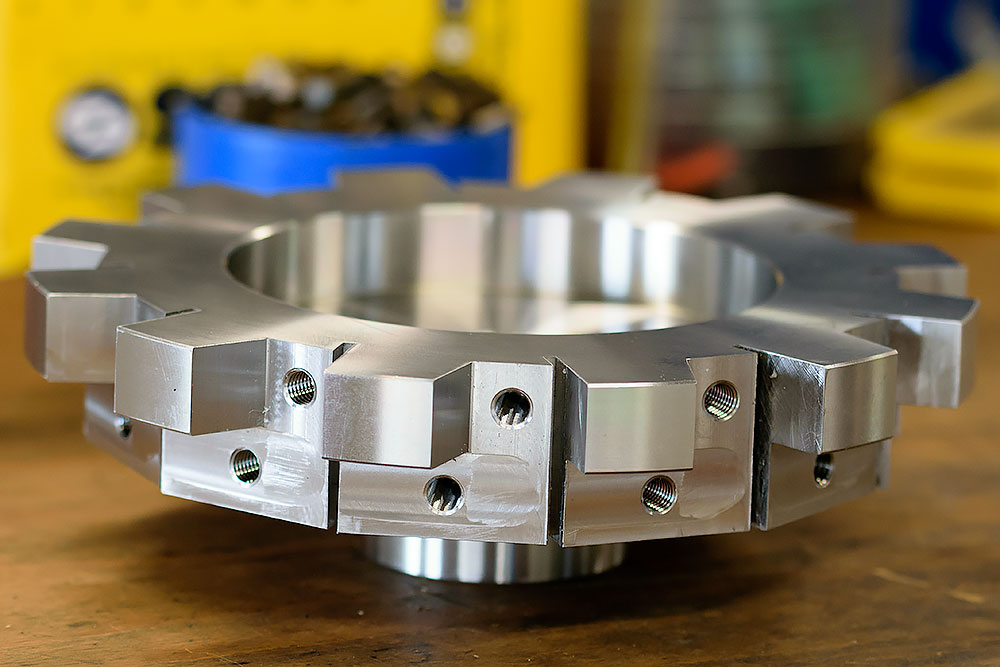

We have many years of experience with CNC milling in aluminum, stainless steel, tool steel, plastic and steel at advanced 4-axis machining centers. Where we with advice and sparring have made many different components and parts for the automation industry, the automotive industry, the food industry, the pump industry, and the offshore industry.

We have supplied more than 3,000,000 components to the automotive industry.

Spaantec is a specialist in machining CNC machining of components in plastic, stainless steel, tool steel, aluminum, brass, and iron as well as other metals. If you have special wishes, ask us, we are always ready with help and advice.

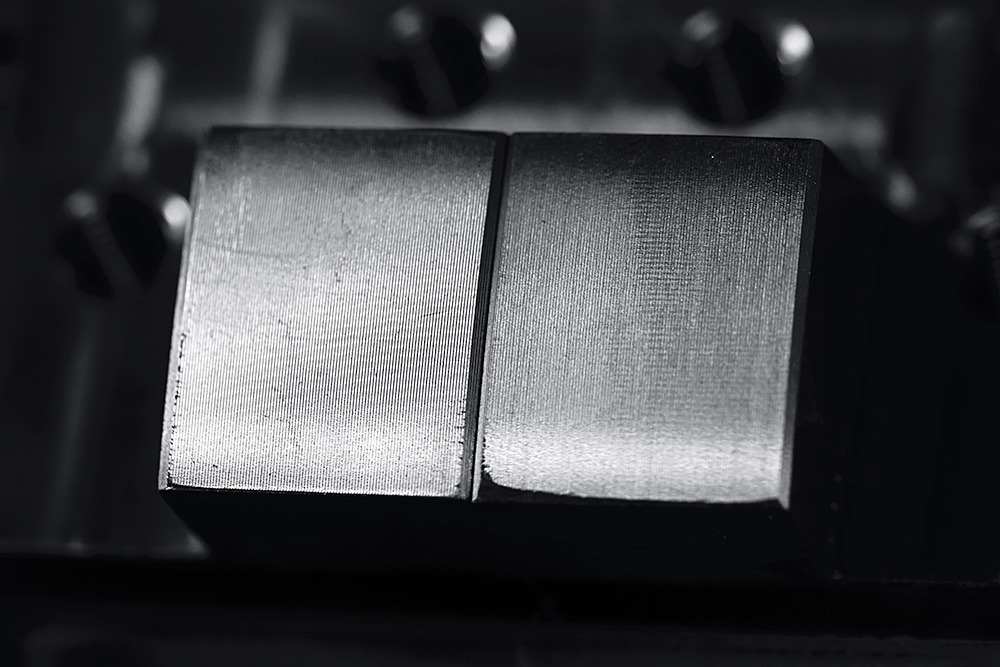

The items we manufacture are of high quality with very high accuracy. Our production is optimized so that we quickly and efficiently switch to and produce new orders. This is a great advantage especially in series production of smaller and larger series.

Based on our many years of experience and competent employees, we produce very advanced components without problems.

We work with machining CNC machining at 4-axis machine centers, where there is room for large items. Dimensions: Max. 2200 x 700 x 700 mm (xyz).

We have many years of know-how and want to ensure our customers a good result. As in the development and production of prototypes, where there are usually a number of technical considerations and testing of material and manufacture. Here, as a customer, you have a great advantage from Spaantec’s specialized knowledge and experience. And it saves time and money.

Let us, therefore, discuss the details before starting the production and CNC milling in stainless steel, tool steel, aluminum, brass, or plastic. Or along the way if the need arises. Contact us today and get a quote on what we can do for you.

All projects with our customers start with an introductory meeting. Here, the project is reviewed in detail with regard to requirements for material, durability, dimensions, tolerances, quality check, delivery ability, delivery security, delivery frequency, delivery time, number of pieces, and other relevant factors.

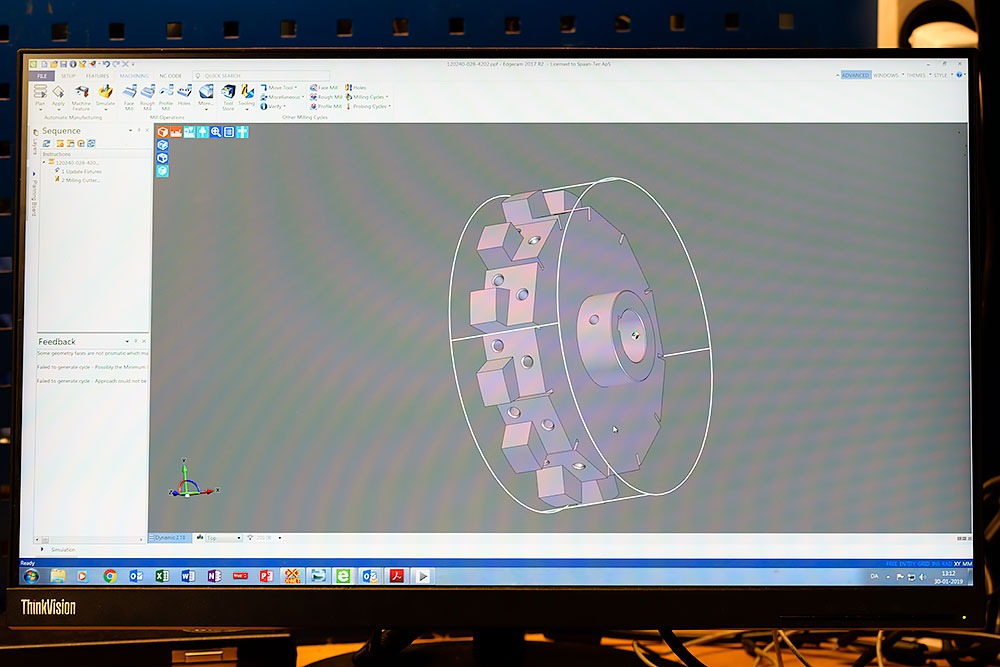

Once the specifications for components and materials have been determined, 2D and 3D CAD drawings will be prepared. They form the basis of how the CNC machine processes the components with the rotating tools.

The drawings deal with the planned CNC milling of the components in aluminum plastic and steel. And they contain information about how the rotating cylindrical drilling and cutting tools move around the components and used in the process to arrive at the finished workpiece.

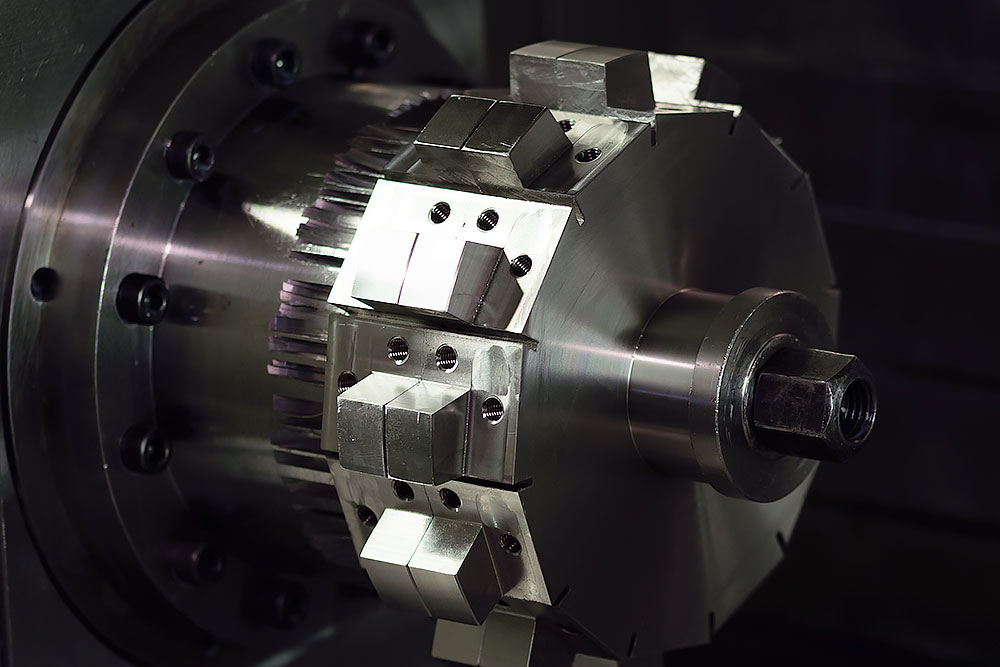

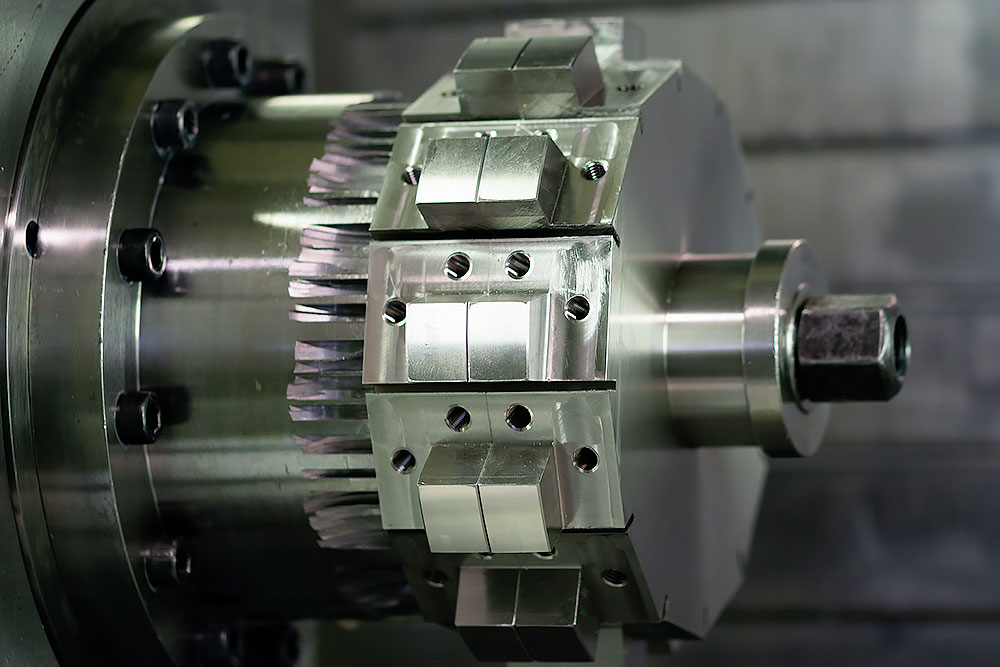

Our 4-axis milling centers have an infinite number of individual setting options. They are able to produce the components you need. No matter what shapes, angles, and tolerances it is the components consist of.

The drawings are entered into the CNC machine’s PC, and they form the basis for the specific CNC milling of the components.

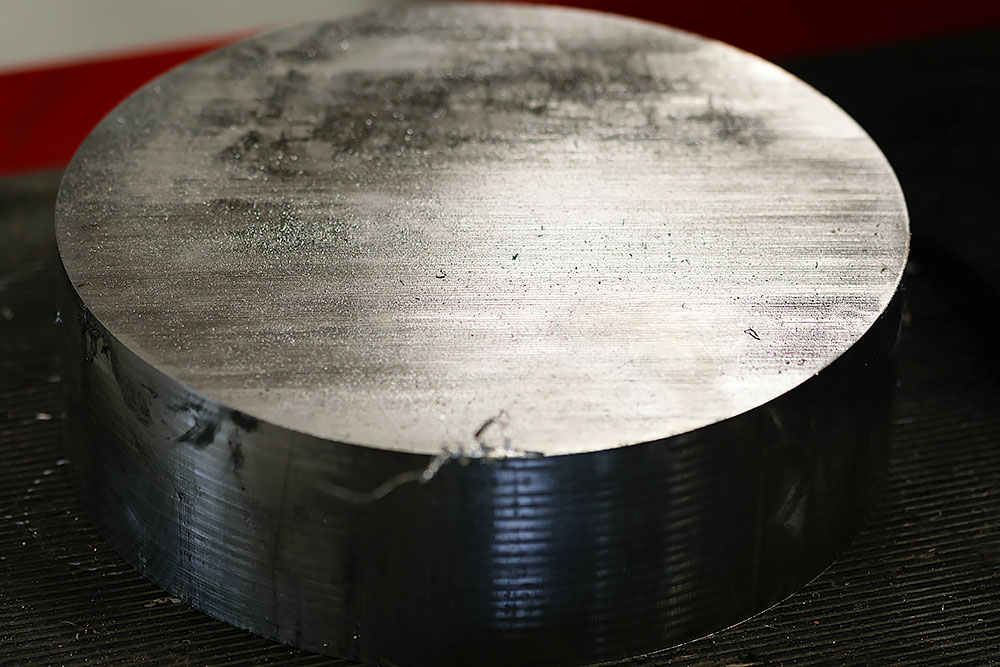

Once the drawing has been retrieved in the machine, the raw workpiece in aluminum, stainless steel, brass, or plastic is clamped with a clamping tool on a milling plane in the CNC machining center. And the machine is then ready to start its CNC milling.

The entire process of the CNC machining, in the form of drilling and milling, is carried out as planned until the finished component appears.

During the CNC milling, a check of process and tolerances takes place on an ongoing basis, with a check of whether requirements and quality are in order, in relation to what has been agreed.

CNC milling in aluminum, stainless steel, tool steel, brass, and plastic is the ideal solution for manufacturing components. Ranging from stand-alone prototypes, over small series of complex parts, and to the manufacture of unique precision components.

Due to the precision, the high accuracy with small tolerances, the fast production with a short production time as well as the uniformly high quality. CNC milling of components in aluminum, stainless steel, tool steel, brass, and plastic is obvious for companies that produce machines and work in the machinery industry, the food industry, the automotive industry, the pump industry, the offshore industry, the shipping industry, the plastics industry, and the iron and metal industry.

Spaantec Aps

Langgade 18, Espe

5750 Ringe

Danmark

Info@spaantec.dk

+45 6266 1822